Shop by Category

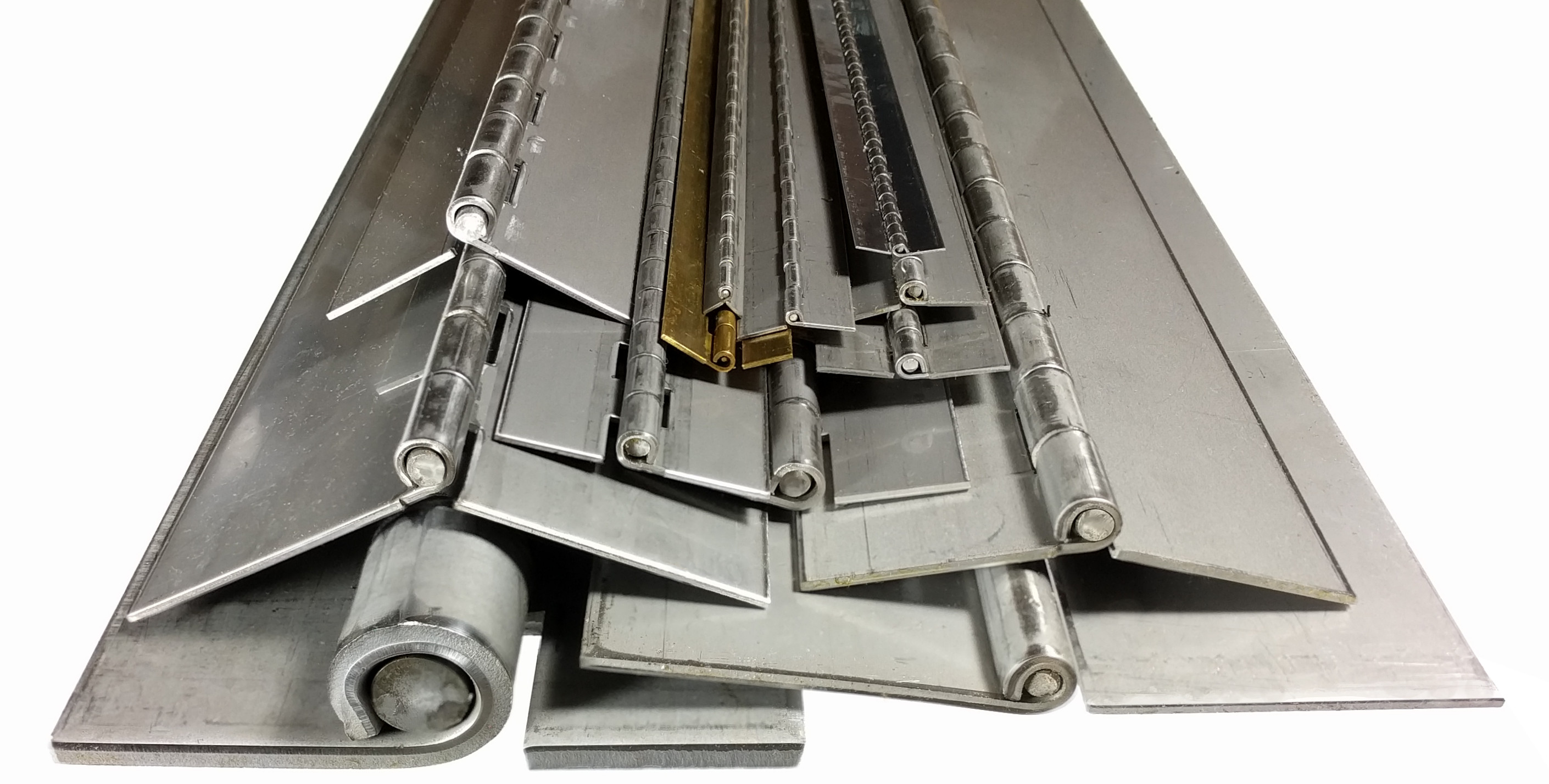

Continuous Hinges

Guden has the largest inventory of continuous hinges anywhere. These are also commonly known as piano hinges, or alternately as known as strips, sticks or lengths of hinge.

- Materials: Steel, Stainless Steel (type 302/304/316), Aluminum (with aluminum pin or stainless steel pin) and Brass

- Size: Usually 6, 7, or 8 feet or longer.

- Applications: Commercial and Military Standards

- Order options: In stock for quick shipment or custom hinges can be provided to meet your individual requirements.

Continuous Hinge Materials & Design

We stock continuous hinges in the three most popular materials of plain steel, stainless steel and aluminum to meet just about every application you can dream up. We also carry a wide range of continuous hinges in plain steel with a brass pin, aluminum with a polished stainless steel pin, 316 stainless, electro-galvanized steel, brass, and zinc and brass plated steel. We carry heavy duty door hinges.

Most of our continuous hinges are available off the shelf without holes and can also be supplied with the hole pattern of your choice. Additional operations such as countersunk holes, cut outs, spring loading, PEM© fasteners, slots, bends, offsets and many other special features can also be supplied.

Choose from all the links below to see the full Guden line of both commercial and military specification continuous hinge.

Piano hinges are popular choices for metal cabinet projects these days. They are available in continuous form or smaller pieces depending on the location and category of use. Guden can supply cut and customized continuous hinges made to a customer's requirements.

What are the Different Types of Piano Hinge?

Continuous hinges are available in various configurations.

The most common configuration is the standard continuous hinge without holes.It is used in an infinite number of industrial applications and is available in a wide selection of sizes.

- We offer from ½" to 6" open widths and from .025" to .250" thick leaves.

- This selection is available in multiple materials and are commonly stocked in 6', 7' and 8' lengths.

Continuous hinges with pre-punched holes are often used in wood cabinet applications, though they can also be used on marine, medical and various other applications.

- The holes can be countersunk with 2" center to center hole locations.

- The sizes range from 1.06" wide to 2" wide in .040" and .060" thick material.

- These pre-punched parts are available in pre-plated nickel or brass, stainless steel, polished stainless steel, electro-galvanized, electropolish and zinc plated.

Additionally there are Plastic Continuous Hinges.

- These are stocked in 100 foot rolls and can be supplied in any length you require.

- Available in black, white and gray.

- They are in stock from 1" to 3" wide.

There are Military Specification continuous hinges, too.

- MS20001 series is an extruded aluminum hinge. These are available in a plain 2024-T3511 or 7075-T73511 alloy aluminum, anodized or chem film finish.

- The hinges are supplied as whole or half hinges (a single leaf with no pin). The half hinge configurations are X, Y, H or backwards H.

- Other military specification continuous hinges are available in a number of series including MS20257, MS35821 to MS35831 and A-A-55589 to A-A-55596.

Are Continuous Hinges Made of Metal or Plastic?

Piano hinges come in different materials, including both metal and plastic. The most common are:

Stainless steel

Stainless-steel piano hinges have excellent corrosion resistance, making them especially ideal for applications exposed to salt spray.

A 304-grade stainless steel piano hinge offers durability and strength. 304 stainless steel is the most common grade used in continuous hinges. For superior corrosion resistance, we stock hinges in type 316 stainless steel as well polished and electropolished stainless steel.

Steel

A steel piano hinge, by the nature of the material, is for doors that endure constant use. The most common alloy used in Guden hinges is either 1010 or 1008 CRS. For additional corrosion resistance, many finishes are available.

Aluminum

Aluminum piano hinges are used when you want lightweight, yet strong and resilient hinges. Heavy duty options are available as well. Aluminum resists rust and corrosion, which is perfect for when exposure to the elements is a factor. They’re also half the weight of brass and carbon steel options. The alloys used are typically 5052 and 3003.

Brass

A polished brass piano hinge is popular when aesthetics are involved. They’re most commonly used on furniture. Other varieties of brass piano hinges are common in architectural applications.

Plastic

Plastic piano hinges are excellent for long life and smooth and quiet operation. These hinges offer a flexible joint, unlike metal piano hinges and are made from one piece of plastic. They tend to be thicker hinges as a way of reinforcing strength.

Guden plastic continuous hinges are made of polypropylene, which stands out for its resistance to oil, salt, water, UV rays and solvents. These hinges should be mounted using fasteners. Adhesives are not recommended.

What Are the Benefits of Using Continuous Piano Hinges?

Piano hinges are a common part of modern sheet metal manufacturing. Benefits include:

- Equal weight distribution

- Easy maintenance

- Durability

- Security

- Workability

Custom Continuous Hinges

Please see the Guden custom hinge selection tool for assistance and guidance in getting the custom hinge that's a perfect fit for your requirements. Easily choose your options, build your custom hinge and submit the information to us for a quick quotation. And for even more continuous hinge design guidelines and help see our Hinge Guidelines.

Our Guden customer service team is also available for assistance and can help you choose the most cost effective solution for your requirements.

Continuous Hinge Resources

Blogs

Guden has a wide range of blogs available if you’re interested in learning more about hinges. You can also view the general hinge FAQs.

- Hinges and Hardware 101 - How to measure your hinge

- Hinges and Hardware 101 - Continuous Hinges

- Hinges and Hardware 101 - Custom Leaf Cut Outs

- THREE Cost-Reducing Tips for your Custom Hinge Design

- Hinges and Hardware 101 - Guden Hinges for the Aerospace Industry

- Hinges and Hardware 101 - How to Retain a Hinge Pin

- Hinges and Hardware 101 - How to Dimension Hole Placement

- Hinges and Hardware 101 - Extruded Aluminum Hinges

- Hinges and Hardware 101 - Pin and Barrel Diameter

- What are the 3 most popular ways to mount a hinge?

- Hinges and Hardware 101- Guden Heavy Duty Hinges

- Hinges and Hardware 101 - Full Knuckles vs Partial Knuckles

Videos

- Guden Custom Hinges

- How to Disassemble and re-assemble a Continuous Hinge

- Guden Product Video - Hinge Angles and Terminology

- Anatomy of a Custom Hinge – Customizations - Part 3 – Offset/Swage

- Guden Quality Hardware

- Guden Selection

- Guden Customer Service

- 7 Industrial Hardware Reasons OEMs LOVE Guden

- Different Types of Hinges – Choosing the right one for your application

- Guden 100 Years Documentary

Continuous Hinge Frequently Asked Questions

What is a Continuous Hinge?

A continuous hinge is typically described as a long hinge with a pin that goes the entire length of the leaves.Continuous Hinge vs. Piano Hinge

A continuous hinge and a piano hinge are the same item. However, the term “Piano Hinge” refers to one of the most iconic uses of the hinge, which you’ll find on the cover of any piano.Piano Hinge Uses

A piano hinge is an excellent choice if your application will undergo excessive use and wear and tear. Since the continuous hinge runs the full length of the door or lid it is applied to, the weight of that door is distributed across the full length of the hinge equally.Which hinge material has the highest corrosion resistance?

- Type 316 stainless steel offers superior corrosion resistance.

- Type 302-304 stainless steel offers great corrosion resistance and strength.

- Aluminum offers adequate corrosion resistance.

- Plain steel offers almost no corrosion resistance but adding a plating or surface treatment increases its resistance.

How much weight can my hinge hold?

What is the reason for different knuckle lengths?

Can I get a custom hinge or one made to my print?

What plating or finishes are available for hinges?

- Zinc, Nickel and Chrome plating

- Passivate, Anodize and Alodine surface treatments

- Painting and Powder Coating

- Buffing, Polishing and Burnishing

How long of a hinge can I get?

What types of operations can typically be done to a hinge?

- Cut-to-length - Hinges can easily be cut down to the exact size you require, or of course supplied in a longer length too.

- Perforations - Holes, slots, obrounds, squares and other shapes can be added to to the leaves.

- Bends - Single or multiple bends can be done as well, depending on the width and thickness of the leaf.

- Swaging and offsets - One of both of the leaves can be swaged or offset to a different plane than the standard. This can achieve a closer fit or make a larger gap between the leaves.

- Corners - Each hinge leaf corner can be clipped or have a radius corner so there is less of a sharp point on each hinge leaf edge.

- Pin Retention - Welding, staking and spinning the pin ends are all popular ways of making sure the pin is difficult to remove.

- Self-Clinching Fasteners - Any number of fasteners can be installed into a hinge to make mounting easier.

- Finishes - Zinc, chrome, and nickel plating, are readily available, as are surface treatments such as passivate, anodize and alodine. Polishing, buffing, burnishing and painting can also be done.