Removable Hinges

Shop by Category

Things to Consider When Choosing a Latch Hinge

Sampling and Testing

Want free Latch Hinge engineering samples? Sure! We know the value of prototyping and testing, and we strive to fill reasonable design sample requests quickly. Building a prototype shouldn't have to be a major expense and an engineering analysis of a prototype is usually the best way to confirm that you have selected a safe and effective product for your application. Working with the right supplier is the key to the success of your design process and you've already made a great choice with Guden, the hardware experts. With almost 100 years of experience, the samples, information and advice you can get from us can be priceless in getting your prototype off the ground and onto the production floor.

Alignment

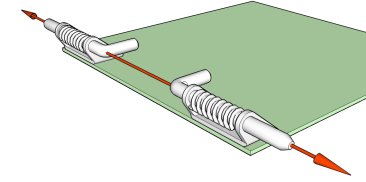

Spring latch hinges are a unique one leaf construction with a spring loaded retractable pin. The pin is bent on one end, and the bend is used to pull the pin back for removal or release of the door or lid. The pin needs to be carefully and accurately in alignment with it's receptacle or the hole in the door to engage the door in place.

Space For Removal

By pulling back on the bent portion of the spring latch hinge pin, the pin retracts and the door or cover is able to be swung down, away, or completely removed without the need for any extra space. This product can also be used on both horizontal and vertical applications. We do not supply a mating female leaf as the typical use has the pin engaging with a hole in the sheet metal chassis or frame.

Typical Uses

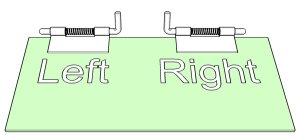

When using it to hinge a door, you typically will use a right hand and a left hand version, pointing in opposite directions to ensure the door is hinged to the frame. For latching applications, you typically can use a single unit on one side to hold the door up or vertical before lowering it or swinging it open. The door or cover will already have another hinge on it that serves as the pivot point.

Right or Left Hand Version

Spring latch hinges are supplied in a right hand version and a mirror image left hand version. The easiest way to tell a right hand from a left hand is to the lay the hinge on a flat surface with the leaf flat on the table and the barrel is on the topside of the leaf. Then make sure that the pin is on the edge of the leaf farthest away from you, not on the edge of the leaf closest to you. If the pin is pointing to the left, it's a left hand version, and vice versa.

Leaf Material and Thickness

| • Cold Rolled Steel – Affordable |

| • Zinc Plated Steel – Affordable and Corrosion Resistant |

| • Type 302/304 Stainless Steel – Corrosion Resistant |

Steel, zinc plated steel and stainless steel are the popular material choices for spring latch hinges.

With or Without Mounting Holes

| • No Holes for Welding |

| • Standard Holes or Slots |

| • Custom Holes or Slot Sizes or Patterns |

| • Custom Threaded Inserts |

Spring latch hinges are available in stock both with and without holes for mounting. Custom holes and slots are also available as a custom request.

Custom Bends / Cuts / Swages

If you are modifying the hinge, it may also be good to compare how cost effective it is to have the supplier do the operations for you. In addition to holes, slots and plating, spring latch hinges can also be cut to width, bent, swaged, and offset - nearly anything is possible. Larger sizes, thicknesses, lengths, and pin styles can also be supplied. Simply provide us with a dimensional drawing to get a price quote.

Finish

| • Chemical Conversion | • Degrease | • Powder-coat |

| • Anodize | • Electro-Galvanize | • Polish |

| • Black Oxide | • Electropolish | • Passivate |

| • Burnished | • Nickel | • Zinc |

| • Chrome | • Paint | • NADCAP |

The majority of stock spring latch hinges are zinc plated steel or stainless steel, but there are also plain steel versions available. Other finishes are also available to suit your application requirements.

Considering a Latch hinge for your application?