Why choose Black Nitrided Rods over Chrome plated Rods

When you’re looking for gas springs, you usually will have the choice of black nitrided or chrome plated rods. But why choose one over the other? Here are five reasons to help you make your decision:

- Environment - While both black nitrided and chrome plated rods are RoHS compliant. Black nitrided rods are much more environmentally friendly in manufacturing and disposal.

- Lifespan - Gas leakage around the seal and rod is the main driver for gas spring life. The less smooth the surface the more gas can escape through miniscule cracks, and possibly create wear on the seal as the rod moves into the tube. Black nitriding provides for a rod surface that’s up to 30% smoother than chrome plating.

- Corrosion Resistance - The black nitriding process infuses nitrogen into the rod surface and case hardens the steel. Black nitride surpasses 150 hours of salt spray testing, while chrome is only around 90 hours.

- Appearance - An all black tube, rod and end connectors makes for a sleeker less eye catching product, while a chrome plated rod can sometimes tend to draw the eye of someone with a gleaming silver color.

- Cost - Last, and certainly maybe the most important, is price. Black nitrided rods are not only a lower cost, but a better value over chrome plated rods due to the many factors mentioned above.

And why not check out our entire line of stock gas springs! All are available with black nitride rods. With such a wide array of sizes, pressures and several end connector options you’re sure to find one that fits your application.

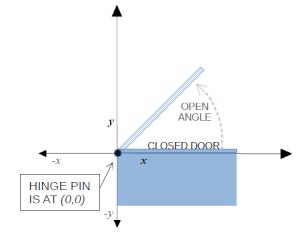

Guden Gas Spring Selector. In the case where you don’t find the size you’re looking for, Guden can also provide a custom size and pressure to meet your requirements. We can even provide assistance in helping you select the right spring for your application and give you guidance for mounting points. Submit your application requirements here and a Guden representative will contact you to discuss your needs.